Stamping Production Line

Welding Production Line

Digital Facilities

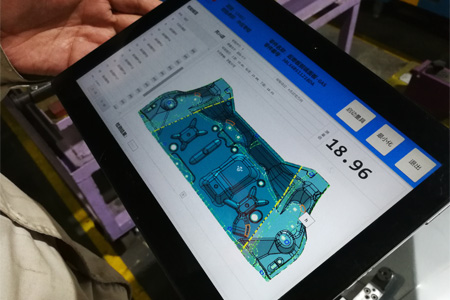

Digital Control

Through the application of hand-held terminal, the production site carries out standardized management of the on-site process, realizes the process implementation controllable and later tracking, and improves the production efficiency and quality.

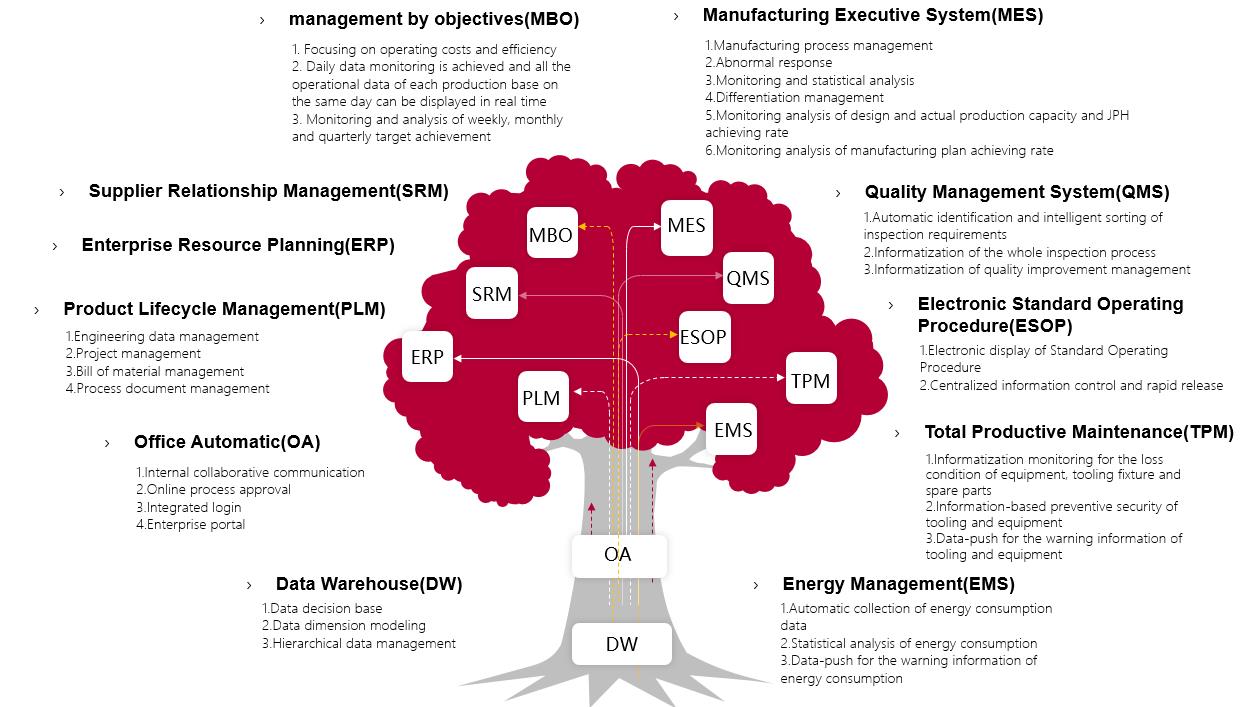

Smart Factory Platform

-

1. Focusing on operating costs and efficiency 2. Daily data monitoring is achieved and all the operational data of each production base on the same day can be displayed in real time 3. Monitoring and analysis of weekly, monthly and quarterly target achiev

-

1.Manufacturing process management 2.Abnormal response 3.Monitoring and statistical analysis 4.Differentiation management 5.Monitoring analysis of design and actual production capacity and JPH achieving rate 6.Monitoring analysis of manufacturing plan ach

-

Automatic identification and intelligent sorting of inspection requirements, informatization of the whole inspection process, and informatization of quality improvement management

-

1.Engineering data management 2.Project management 3.Bill of material management 4.Process document management

-

1.Informatization monitoring for the loss condition of equipment, tooling fixture and spare parts 2.Information-based preventive security of tooling and equipment 3.Data-push for the warning information of tooling and equipment

-

1.Automatic collection of energy consumption data 2.Statistical analysis of energy consumption 3.Data-push for the warning information of energy consumption

-

1.Electronic display of Standard Operating Procedure 2.Centralized information control and rapid release

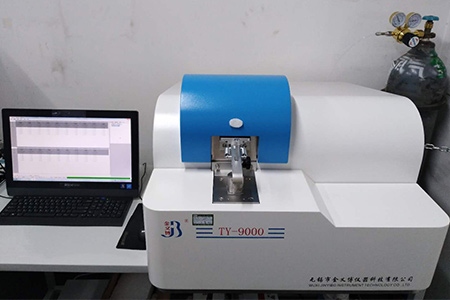

Professional Testing Technology

The laboratory has the ability to carry out more than 20 kinds of routine tests, and has long-term cooperation with many domestic experimental testing institutions

©2021 Chongqing Zhixin Industrial Co., Ltd. No. 11003737

©2021 Chongqing Zhixin Industrial Co., Ltd. No. 11003737